Introduction

A careful evaluation of your disorders surrounding a conveyor is critical for correct conveyor chain selection. This segment discusses the fundamental concerns essential for successful conveyor chain choice. Roller Chains tend to be utilized for light to moderate duty materials managing applications. Environmental conditions may well call for using unique supplies, platings coatings, lubricants or the capability to operate devoid of supplemental external lubrication.

Essential Data Needed For Chain Selection

? Type of chain conveyor (unit or bulk) like the technique of conveyance (attachments, buckets, via rods and so on).

? Conveyor layout which includes sprocket locations, inclines (if any) as well as the amount of chain strands (N) to get employed.

? Amount of materials (M in lbs/ft or kN/m) and style of material for being conveyed.

? Estimated excess weight of conveyor parts (W in lbs/ft or  kN/m) including chain, slats or attachments (if any).

kN/m) including chain, slats or attachments (if any).

? Linear chain pace (S in ft/min or m/min).

? Environment in which the chain will operate which includes temperature, corrosion circumstance, lubrication situation and so on.

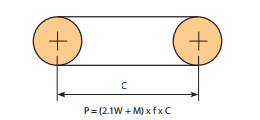

Step one: Estimate Chain Tension

Make use of the formula under to estimate the conveyor Pull (Pest) after which the chain stress (Test). Pest = (M + W) x f x SF and

Test = Pest / N

f = Coefficient of Friction

SF = Pace Issue

Phase 2: Make a Tentative Chain Variety

Working with the Test worth, produce a tentative selection by picking out a chain

whose rated operating load higher than the calculated Test value.These values are appropriate for conveyor service and are diff erent from individuals shown in tables at the front on the catalog which are associated with slow speed drive chain utilization.

Additionally to suffi cient load carrying capability normally these chains has to be of a selected pitch to accommodate a preferred attachment spacing. For instance if slats are for being bolted to an attachment every single 1.5 inches, the pitch from the chain selected ought to divide into one.5?¡À. Thus a single could use a 40 chain (1/2?¡À pitch) with all the attachments every 3rd, a 60 chain (3/4?¡À pitch) using the attachments every single 2nd, a 120 chain (1-1/2?¡À pitch) using the attachments each and every pitch or perhaps a C2060H chain (1-1/2?¡À pitch) with all the attachments each and every pitch.

Step three: Finalize Assortment – Calculate Real Conveyor Pull

Following producing a tentative variety we have to confirm it by calculating

the actual chain stress (T). To complete this we ought to fi rst calculate the real conveyor pull (P). Through the layouts shown within the correct side of this webpage opt for the acceptable formula and determine the complete conveyor pull. Note that some conveyors could be a mixture of horizontal, inclined and vertical . . . in that case calculate the conveyor Pull at each and every segment and include them collectively.

Phase four: Calculate Highest Chain Tension

The utmost Chain Stress (T) equals the Conveyor Pull (P) as calculated in Stage three divided through the variety of strands carrying the load (N), instances the Speed Issue (SF) proven in Table two, the Multi-Strand Aspect (MSF) proven in Table 3 as well as the Temperature Issue (TF) shown in Table four.

T = (P / N) x MSF x SF x TF

Stage five: Test the ?¡ãRated Doing work Load?¡À with the Chosen Chain

The ?¡ãRated Doing work Load?¡À of your chosen chain really should be greater than the Optimum Chain Tension (T) calculated in Stage four above. These values are suitable for conveyor services and therefore are diff erent from individuals shown in tables in the front with the catalog which are associated with slow pace drive chain usage.

Phase 6: Check the ?¡ãAllowable Roller Load?¡À of your Selected Chain

For chains that roll to the chain rollers or on prime roller attachments it can be essential to check out the Allowable Roller Load?¡À.

Note: the Roller load is established by:

Roller Load = Wr / Nr

Wr = The complete fat carried by the rollers

Nr = The quantity of rollers supporting the excess weight.