Product Description

Product Description

Dry couplings are the smart choice for the transportation of hazardous fluids.Compared with traditional couplings, it greatly improves the connection speed: during the unloading process, the built-in valve of the coupling is closed in advance, avoiding the liquid leakage or volatilization to the surrounding environment, reducing the chance of the operator coming into contact with the toxic medium, and safeguarding the safety of the personnel. The female end of the connection with the pipeline has an integrated swivel function, which reduces the fatigue damage of the pipeline.

Advantages:

√ Easy handling through high transmission ratio

√ Self-locking when fully connected

√ Integrated swivel joint

√ Lightweight

√ Minimal maintenance

√ Field-oriented function principles

√ Approval in accordance to WHG (DIBT-Approval is incl.)

√ Approval in accordance to ATEX Zone 1

Application:

– For fast and secure fluid transfer like lye and acids, fuels and oils, seawater, tap water, waste water, gas, superheated steam, compresses air, LPG, sludge, foodstuffs, pharmaceutical products between pipes, hoses, tanks and equipment.

– Widely used in power station construction, chemical and pharmaceutical industry, oil industry, offshore drilling, shipbuidling, loading/unloading(aircraft, tank trucks, filling stations, ships), tank cleaning, and food beverage industry.

Product Parameters

Dry Coupling Parameters:

| Product name | Dry Quick Break Coupling |

| Customized support | OEM, ODM |

| Place of Origin | ZheJiang , China |

| Technics | Casting |

| Materials | Stainless steel / Brass / AL, More Customized |

| Connection | Male and Female |

| Size | 3/4″-2″ |

→ Click to View More Hoses and Other Fittings.

Cooperation

RUNXI’s products are exported to more than 30 countries, such as Iran, Russia, USA, The UK, DAE, Korea, Vietnam, Iraq, Singapore, Indonesia, Azerbaijan and Japan,and some African countries, etc. We have obtained high praise from clients domestic and abroad due to the excellent quality and competitive price.

At RUNXI & JIAYAO Company, emphasis is placed on human resource development as we believe in the Group’s philosophy “Organization Development through Self Development”. We have competent professionally qualified and experienced staff in each of our functions. The Company assists & encourages its employees for their professional qualifications and also invests in developing staff through in-house, out-sourced and international training.

Company Profile

JIAYAO CO., LTD.(For manufacturing) & HangZhou RUNXI INTERNATIONAL TRADE CO., LTD. (For export) are located in Yuying Street, Guangchuan Town, Jing County, HangZhou City, ZheJiang Province, China. we are a technology-based enterprise which is specialized in the area of R&D, marketing of multiply rubber products, rubber hose production line and telecommunication towers.

Our company specializes in Telecom towers, High pressure hoses, Hydraulic hoses, SAE & DIN series hoses, Drilling Rotary hose, Choke & Kill Line, Bop hoses, Suction and Discharge hose, Fabric hoses, Metal Flexible hose, Fireproof hose, Silicone hose, Hose Assembly, and Hose Production Line, etc.

Packaging & Shipping

Certifications

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white wearable woven bags. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 20 to 60 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

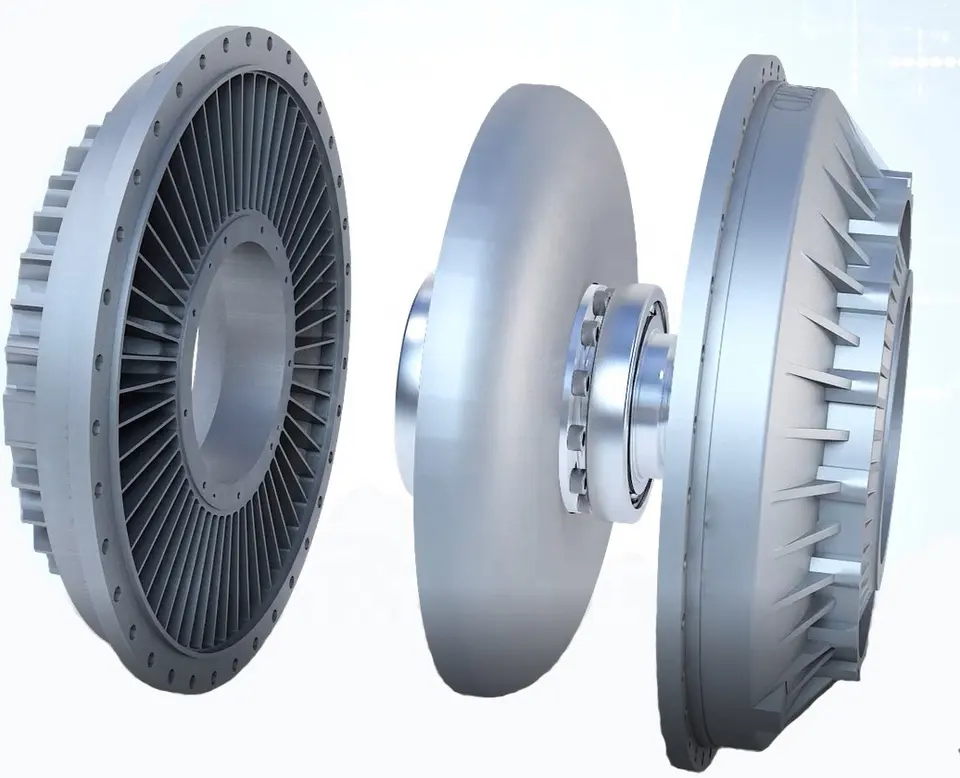

Role of Fluid Couplings in Heavy-Duty Mining Equipment

Fluid couplings play a critical role in heavy-duty mining equipment, offering several advantages that enhance the performance, safety, and longevity of the machinery:

- Soft Start: In mining applications, where large equipment like crushers, conveyors, and draglines are involved, fluid couplings provide a soft start to the motor, gradually ramping up the torque and reducing the shock and stress on the drivetrain. This ensures smoother equipment startup and prevents sudden power demand spikes.

- Torque Limiting: Fluid couplings act as torque limiters, protecting the equipment from sudden overloads and torque surges during operations. This feature prevents damage to the motor, gearbox, and driven components, thus increasing the reliability and lifespan of the equipment.

- Load Distribution: In mining equipment with multiple driven components or motors, fluid couplings enable efficient load distribution among the components. This ensures that each component shares the load appropriately, preventing uneven wear and improving overall system efficiency.

- Overload Protection: The inherent slip feature of fluid couplings allows them to slip at high loads, providing overload protection to the equipment. In case of unexpected jams or blockages in conveyor belts or crushers, the fluid coupling can slip, preventing costly damage to the equipment.

- Vibration Damping: Mining operations can generate significant vibrations that can be damaging to the equipment. Fluid couplings help dampen vibrations, reducing stress on the components and minimizing wear and tear.

- Reduced Maintenance: By preventing sudden torque surges and overloads, fluid couplings reduce the need for frequent maintenance and repairs, saving both time and money for mining operators.

Heavy-duty mining equipment operates in harsh and challenging environments with high loads and abrasive materials. Fluid couplings used in mining applications are designed to be robust, durable, and resistant to contaminants like dust and water.

Overall, fluid couplings play a vital role in ensuring the efficient and reliable operation of heavy-duty mining equipment, contributing to increased productivity and reduced downtime in mining operations.

Fluid Couplings in High-Temperature Environments

Fluid couplings are versatile power transmission devices commonly used in various industrial applications. However, their suitability for high-temperature environments depends on several factors, including the design, materials, and the specific operating conditions.

Here are some key considerations regarding the use of fluid couplings in high-temperature environments:

- Fluid Type: The type of fluid used inside the coupling greatly influences its temperature capabilities. Some fluid couplings are designed to handle higher temperatures by using specially formulated high-temperature fluids that can withstand elevated heat levels without degradation.

- Materials: The materials used in the construction of the fluid coupling play a crucial role in determining its maximum temperature tolerance. High-quality materials with good heat resistance properties are required to ensure reliable performance in high-temperature conditions.

- Lubrication: Proper lubrication is essential to reduce friction and heat generation within the fluid coupling. In high-temperature environments, ensuring sufficient and appropriate lubrication is crucial to prevent excessive wear and potential damage.

- Cooling: Some fluid couplings come equipped with cooling systems, such as cooling fins or external cooling circuits, to dissipate excess heat generated during operation. These cooling mechanisms can enhance the coupling’s capacity to handle higher temperatures.

- Application Considerations: The specific application and load requirements must be taken into account. In some cases, high-temperature conditions may be intermittent or occasional, allowing the fluid coupling to cool down between cycles. However, continuous high-temperature operation may require a more robust and specialized fluid coupling.

It is important to consult with the fluid coupling manufacturer to understand the temperature limitations and performance capabilities of their products. Manufacturers can provide guidance on selecting the appropriate fluid coupling for specific high-temperature applications.

While fluid couplings can be suitable for moderate to high-temperature environments, it is essential to operate them within their specified temperature range to ensure optimal performance and longevity. Extreme temperatures beyond the coupling’s rated limits can lead to accelerated wear, reduced efficiency, and potential damage, ultimately affecting the reliability of the power transmission system.

In summary, fluid couplings can be used in high-temperature environments, provided that the coupling’s design, materials, and lubrication are suitable for the specific application and operating conditions. Regular maintenance and adherence to the manufacturer’s guidelines are essential to ensure reliable performance and durability in such environments.

Types of Fluid Used in Fluid Couplings

Various types of fluids can be used in fluid couplings depending on the specific application and requirements. Some common types of fluids used in fluid couplings include:

- Oil: Mineral oil is one of the most commonly used fluids in fluid couplings. It offers good lubrication properties and thermal stability, making it suitable for a wide range of operating conditions. Oil-based fluids are generally cost-effective and readily available.

- Water-Glycol: Water-glycol mixtures are often used in fluid couplings that require fire-resistant properties. These mixtures provide improved cooling and are less flammable compared to pure oil fluids. They are commonly used in applications where fire safety is a concern, such as in mining and underground operations.

- Synthetic Fluids: Synthetic fluids, such as synthetic oils and silicone-based fluids, offer enhanced performance characteristics over mineral oils. They can withstand higher temperatures and provide better thermal stability, making them suitable for more demanding industrial applications.

- Biodegradable Fluids: In environmentally sensitive applications, biodegradable fluids are used to reduce the environmental impact in case of accidental leaks or spills. These fluids are designed to break down naturally and are commonly used in applications like forestry and marine operations.

The choice of fluid depends on factors such as the required power transmission efficiency, operating temperature, fire safety requirements, and environmental considerations. It is essential to select the appropriate fluid that matches the specific needs of the fluid coupling and the machinery or equipment it is used in.

editor by CX 2024-05-07