Product Description

Product Description

Aluminum Compressed Air Pipe

HangZhou CHINAMFG Fluid Technology Co., Ltd. presents the Aluminum Compressed Air Pipe, a reliable and efficient solution for connecting pipes. With its isometric direct connection, this pipe offers numerous benefits for English-speaking natives.

Simple and Fast Installation

The main feature of our Aluminum Compressed Air Pipe is its direct butt jointing, eliminating the need for additional joints or connecting devices. This results in a simple and fast installation process, saving valuable time and reducing labor costs. By aligning and tightly connecting 2 aluminum pipes of equal diameter, the connection can be completed effortlessly.

Tightness and Reliability

Our equal diameter direct connection method ensures the tightness and reliability of the pipe connection. Through proper connection process and technology, the pipes are completely sealed, effectively preventing compressed air leakage. This tight connection guarantees efficient system operation and enhances overall working efficiency.

Low Resistance and Pressure Loss

With no additional joints or connecting devices, our aluminum alloy compressed air piping offers low resistance and pressure loss. This design minimizes flow resistance within the pipe, resulting in reduced pressure loss. As a result, air transfer efficiency is improved, leading to lower energy consumption.

Choose HangZhou CHINAMFG Fluid Technology Co., Ltd.’s Aluminum Compressed Air Pipe for a reliable, efficient, and cost-effective solution for your pipe connection needs.

Product Parameters

| S.N | Norminal diameter (mm) | W(mm) | H(mm) | |

| DN20 | 48 | 52 | ||

| DN25 | 53 | 52 | ||

| DN40 | 81 | 75 | ||

| DN50 | 91 | 75 | ||

| DN65 | 124 | 106 | ||

| DN80 | 141 | 106 | ||

| DN100 | 158 | 106 | ||

| DN125 | 181 | 106 | ||

| CC 5710 30 | DN148 | 225 | 130 | |

| BB 5710 30 | DN200 | 281 | 130 |

| 1. Complete Reliability | Removable and reusable components, perfect for your factory environment Fast installation of shunt device and branch pipeline, convenient adjustment of production line Rich interfaces and accessories, suitable for any system All components are nonflammable |

| 2. Better Corrosion Resistance than 304 Stainless Steel | Anti-corrosion Internal Surface Treatment of Aluminum Alloy Pipe Alkali and acid corrosion resistance Internal surface always clean, no pressure loss of the pipe network system |

| 3. Easy Operation | Pipelines and connectors can be installed immediately without additional treatment — no pre construction preparation is required Fast assembly, no welding, gluing or stranding required – time saving Easy assembley- no need for training Light weight, easy for cutting pipes — easier to work on site Directly use — the system can be tested and used immediately |

| 4. Energy Saving | Consistently high quality interior surfaces – clean air Low friction of inner surface — high flow performance Precise pipe diameter – optimized sealing Automatic filling type large contact surface sealing system ,no leakage |

| 5. Excellent Resistance against the Following Environments | Corrosion Mechanical vibration Thermal variations U.V Compressor oil |

| 6. Durable, Beauty | Electrostatic spraying when leaving the factory Standard color, beautiful appearance |

Equal Pipe to Pipe Connector

Introducing the Water/Air/Oil Fluid Transportation Pipes Fittings Pipe to Pipe Connector Coupling from HangZhou CHINAMFG Fluid Technology Co., Ltd. This high-quality pipe fitting offers a press connection and comes with a ten-year quality guarantee. Perfect for gas pipes, plumbing fittings, and more. Get yours today!

Product Category & Application

HangZhou CHINAMFG Fluid Technology Co., Ltd. specializes in sustainable, efficient, and energy-efficient fluid transportation systems. Our water/air/oil pipes and fittings, including pipe-to-pipe connectors and couplings, ensure reliable connections. With a ten-year quality guarantee and press connection, our products provide excellent performance and durability. Choose our pipe fittings for your plumbing needs!

Company Profile

HangZhou CHINAMFG Fluid Technology Co., Ltd.

HangZhou CHINAMFG Fluid Technology Co., Ltd. is a manufacturing company specializing in aluminum pipe, pipe fittings, and industrial aluminum profiles. We are dedicated to research and development, production, sales, and installation. Our company is located in the economic and technological development zone of HangZhou, ZheJiang , covering a floor space of 200 mu with a total investment of 180 million yuan.

With our state-of-the-art production and inspection equipment, including mold center, inspection center, R&D, and other equipment imported from Germany, South Korea, and Japan, we have become a large-scale aluminum alloy manufacturer with first-class technical equipment.

Our production facilities include 5 aluminum alloy tube extrusion production lines, 3 deep processing production lines for finished products, and 2 production lines for industrial aluminum profiles. This enables us to have an annual production capacity of 3,000 tons of aluminum alloy pipes and 8,000 tons of industrial aluminum profiles.

At HangZhou CHINAMFG Fluid Technology Co., Ltd., we are committed to delivering high-quality products that meet the needs of our customers. Our aluminum pipes, pipe fittings, and industrial aluminum profiles are designed to provide durability, reliability, and excellent performance. Whether you need aluminum products for industrial applications or other purposes, we have the expertise and resources to meet your requirements.

HangZhou CHINAMFG Fluid Technology Co., Ltd.

The company specializes in the innovation and deep processing of non-ferrous materials. We are proud to introduce our range of high-quality pipes and pipe fittings that cater to the diverse needs of customers worldwide.

- High Intensity Aluminum Alloy Pipe: Our high-intensity aluminum alloy pipe is designed to meet the highest industry standards. It offers exceptional strength and durability, making it perfect for various applications.

- Stainless-Steel Pipe: Our stainless-steel pipe is crafted with precision and expertise. It provides excellent corrosion resistance and is ideal for use in demanding environments.

- Copper-Aluminum Composite Pipe: Our copper-aluminum composite pipe combines the advantages of both materials. It offers superior heat transfer performance and is widely used in heating and cooling systems.

- Aluminum Pipe with Internal Thread: Our aluminum pipe with internal thread is designed for easy installation and secure connections. It is suitable for a wide range of applications, including plumbing and industrial projects.

- High-Frequency Welding of Aluminum Alloy Collector Pipe and Pipe Fittings: Our high-frequency welding technology ensures strong and reliable joints. This collection of aluminum alloy collector pipes and pipe fittings is perfect for fluid transportation systems.

With our commitment to innovation and customer satisfaction, we strive to provide more diversified and superior products. Choose HangZhou CHINAMFG Fluid Technology Co., Ltd. for all your non-ferrous material needs.

Exhibition

Certifications

After Sales Service

Ten-year Quality Guarantee

At HangZhou CHINAMFG Fluid Technology Co., Ltd., we are proud to offer a ten-year quality guarantee on our UPIPE series product. If you encounter any quality problems within 10 years from the installation and acceptance of the product, we will replace or repair it free of charge.

However, please note that there are certain situations where the guarantee does not apply. These include:

- The product or component is no longer within the warranty period, unless it has an extended quality assurance service.

- The product has not been installed according to our stipulations or has been used outside of the applicable scope specified by our company. This also includes failure to operate the product according to our company’s manual and relevant installation and maintenance documents, or using it in an environment that goes against our stipulations. Any damage caused by improper installation, storage, or operation, such as exposure to excessively high or low temperatures, corrosive environments, or external forces, is not covered.

- The breakdown or damage is a result of unauthorized installation, repair, modification, or dismounting carried out by our company’s after-sales personnel or a designated service agent, unless it is performed by a third-party after-sales service agency entrusted by our company.

With our ten-year quality guarantee, you can have peace of mind knowing that your UPIPE series product is protected. Trust HangZhou CHINAMFG Fluid Technology Co., Ltd. for reliable and durable solutions.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

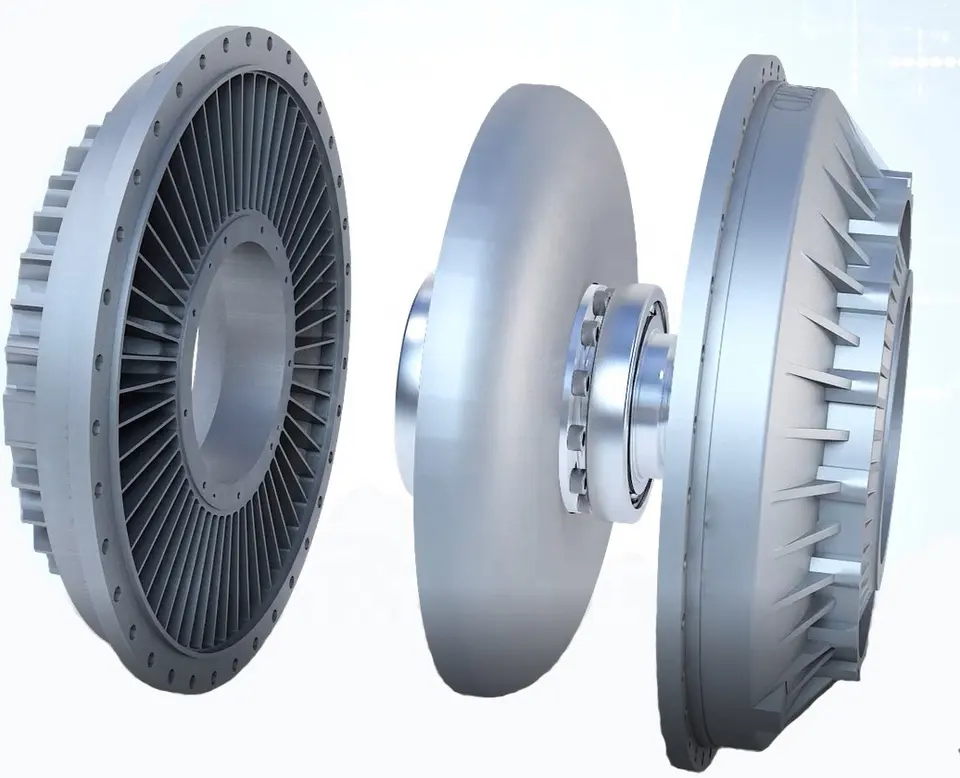

Handling Overloads and Stall Conditions in Fluid Couplings

A fluid coupling is designed to handle overloads and stall conditions in power transmission systems. When an overload or stall occurs, the fluid coupling utilizes its unique operating principle to protect the drivetrain and the connected machinery:

- Slip Feature: One of the key characteristics of a fluid coupling is its ability to slip at high torque loads. When an overload situation arises, the fluid coupling allows some relative motion between the input and output sides, known as slip. This slip absorbs the excess torque and prevents it from being transferred to the driven equipment, effectively protecting it from damage.

- Fluid Circulation: During normal operation, the fluid inside the coupling circulates smoothly between the impeller and turbine, transmitting torque with minimal losses. However, when an overload or stall condition occurs, the fluid circulation may become turbulent, generating heat in the process. This heat dissipation helps in absorbing and dissipating the excess energy, preventing the transmission system from experiencing sudden stress.

- Automatic Reconnection: After an overload or stall condition, once the excess torque is dissipated through slip and heat, the fluid coupling automatically reconnects the input and output sides, resuming the power transmission. This automatic reconnection ensures that the system returns to normal operation once the overload situation is resolved.

- Sturdy Construction: Fluid couplings are designed with robust and durable materials to withstand high torque and thermal stresses during overload conditions. The strong construction ensures that the fluid coupling remains reliable and operational even after multiple overload events.

Overall, a fluid coupling’s ability to handle overloads and stall conditions makes it a reliable and essential component in various industrial applications. By providing overload protection and slip characteristics, fluid couplings help prevent costly damage to equipment, increase operational safety, and contribute to the longevity of the entire power transmission system.

Fluid Couplings for Soft-Start Applications in Conveyor Systems

Yes, fluid couplings are well-suited for soft-start applications in conveyor systems. Soft-starting is the gradual acceleration of the conveyor belt to reduce sudden mechanical stress and current spikes during startup. Fluid couplings provide a smooth and controlled method of power transmission, making them ideal for achieving soft-start capabilities in conveyor systems.

When a conveyor system equipped with a fluid coupling starts, the fluid inside the coupling initially acts as a viscous medium, allowing the input and output shafts to rotate at different speeds. As the fluid coupling fills with fluid, it gradually transmits torque and smoothly accelerates the conveyor belt.

One of the significant advantages of using fluid couplings for soft-start applications is that they provide adjustable startup times. By controlling the amount of fluid inside the coupling, the startup acceleration rate can be precisely tuned to match the specific requirements of the conveyor system.

The soft-start feature offered by fluid couplings helps in several ways:

- Mechanical Stress Reduction: The gradual acceleration minimizes mechanical stress on the conveyor belt, pulleys, and other components, leading to extended equipment life and reduced maintenance costs.

- Energy Savings: Soft-starting prevents sudden current spikes and reduces the power demand during startup, resulting in energy savings and improved efficiency.

- Improved Conveyor Belt Life: By avoiding abrupt starts, the wear and tear on the conveyor belt are reduced, leading to longer belt life and decreased downtime.

- Enhanced Conveyor Control: Soft-start capabilities enable better control over the conveyor system, allowing operators to optimize the material flow and prevent product spillage or jamming.

Fluid couplings offer reliable and cost-effective soft-start solutions for conveyor systems across various industries, including mining, manufacturing, and material handling. They are particularly beneficial when dealing with heavy loads or long conveyor belts, where the avoidance of sudden shock loads is critical.

In summary, fluid couplings are a popular choice for soft-start applications in conveyor systems due to their smooth and controlled power transmission, adjustable startup times, and the ability to reduce mechanical stress and energy consumption during startup.

Controlling Torque and Rotational Speed with Fluid Couplings

A fluid coupling plays a crucial role in controlling torque and rotational speed in power transmission systems. The principle behind its operation allows for smooth torque transmission while offering some level of speed control:

- Torque Transmission: When power is applied to the input side (also known as the driving side) of the fluid coupling, the impeller starts to rotate and accelerates the transmission fluid inside the housing. The kinetic energy of the moving fluid creates a rotating flow pattern that transfers torque to the output side (also known as the driven side) of the coupling. This torque transfer enables the connected machinery or equipment to start smoothly without any shock loading.

- Slip: In a fluid coupling, there is always a slight difference in speed between the input and output sides due to the viscous nature of the fluid. This speed difference is known as slip. The slip allows the fluid coupling to protect the connected components from sudden torque spikes and vibrations. If the output side experiences an abrupt load increase or jam, the slip absorbs the excess torque, preventing damage to the drivetrain.

- Speed Control: While fluid couplings are not as efficient in speed control as variable-speed drives, they do offer some inherent speed control characteristics. The amount of slip in the fluid coupling affects the output speed relative to the input speed. By adjusting the fill level of the fluid coupling or using different fluid viscosities, it is possible to fine-tune the speed at which the output shaft rotates. However, it’s important to note that this speed control is limited compared to other speed control mechanisms.

Overall, fluid couplings provide a reliable and efficient means of controlling torque during power transmission. Their ability to dampen torsional vibrations and provide overload protection makes them suitable for various applications where smooth torque transfer and protection against shock loads are essential.

editor by CX 2024-02-24